FAQ

Lightning eMotors Technology

Lightning eMotors creates the LEV powertrain and works with OEMs and upfitters to have the powertrain installed on an OEM chassis turning that vehicle into an all-electric van, truck, or bus. The LEV powertrain consists of an electric motor, transmission, power electronics, integrated control system, charging system, and batteries.

The Lightning Electric is a Zero Emission Vehicle. It runs wholly on electric power meaning there are no tailpipe emissions, so it is a great fit for air quality controlled areas, and to generally improve your community’s air quality.

Lightning eMotors is a provider of premium commercial electric vehicle powertrains. The components used in our powertrains, including the electric machine, batteries, and power electronics, are all sourced from proven suppliers with miles of on-road validation. Combined with elegant integration and premier industry partnerships, the different LE configurations offer flexibility on proven, industry adopted platforms. With different charging modes offered, including Level 3 DCFC, Lightning Electric vehicles require no gasoline or diesel and are designed to provide the range you need.

• Electric machine – Our suppliers’ electric motors provide industry-leading power and torque density while reducing the amount of active materials, such as magnets and copper. Our electric motors all have millions of miles of on-road validation. In addition, electric motors have very few wearable components, leading to fewer required preventative maintenance tasks and lower overall service costs versus an internal combustion engine.

• Batteries – We only use the highest quality batteries and battery management systems with years of on-road performance in consumer vehicles. Our batteries use precise active thermal management, meaning our powertrains can control battery temperatures to heat above or cool below environmental ambient temperature. This active thermal management translates to improved performance and longer life.

• DC Fast Charging (DCFC) – DCFC allows our vehicles to be charged to 80% in as few as 45 minutes (charge time depends on the platform, charging station output, and total kWh battery capacity). Currently, our vehicles can accept up to 50 kW output. All of our vehicles utilize industry-standard charging connectors, SAE J1772 CCS.

• Seamless and Professional Integration – Our engineers work tirelessly to ensure our powertrains are integrated into vehicles so that they function in an expected and intuitive fashion, requiring little to no additional training. With smooth, powerful, and quiet propulsion, many customers have said that the Lightning Electric driving experience is better than conventional vehicles.

• Lightning eMotors works with top vehicle upfitters in the industry to provide installation of our powertrains—in some cases, the builders are the ones which assemble the conventional vehicle.

• Lightning Analytics – Our team of fleet experts and data scientists access and study the real-time vehicle data coming from all Lightning Electric vehicles. This data is analyzed and reported to you to help you get a deep understanding of your fleet’s vehicle efficiency, driver behavior, route dynamics, and vehicle HVAC energy consumption.

DC Fast Charge (up to 50 kW) with CCS (SAE J1772 Combo)

• Lightning Analytics: a cloud-based fleet telematics and analytics solution integrates with other fleet management software your fleet may use. An optional, easy to use customized dashboard provides driver behaviors, preventative maintenance, route optimization and more – all in real-time. Encrypted connections protect your vehicle data.

As with most EVs, some high-voltage battery power is consumed when the vehicle is not in use for what’s known as “keep-alive” mode, where the battery monitoring system and thermal management system preserve optimal battery conditions to reduce strain and increase the life of the batteries. The amount of power consumed during this state is a function of environmental conditions, battery state-of-charge (SoC), and other vehicle variables. We recommend plugging in the vehicle when not in use to allow the charger to supply the keep-alive power instead of reducing the vehicle batteries’ SoC.

Inductive charging is currently not available, but it is on our roadmap for future integration as the technology matures.

Performance

The LEV utilizes a three-phase permanent magnet electric traction motor. Peak motor power can range from 215 HP/160kW – 291HP /220kW. Peak torque can range from 733 lb-ft/994 Nm to 823 lb-ft/2471 Nm).

*Data depends on the platform. Consult individual platforms on our website or a sales representative for each vehicles values

All-electric range can vary depending on route or drive cycle, environmental conditions, vehicle or equipment configurations, and driver behavior. Use of auxiliary power systems such as HVAC will reduce range.

The Lightning Electric Powertrain fully integrates the conventional vehicle instrument cluster. The cluster’s readout has been redesigned to show the new vehicle metrics using the stock OEM appearance and look, and all instruments remain functional. Lightning eMotors has a proprietary mobile application that displays various details such as battery state of charge, range, and miles until empty, location, and other metrics.

Cruise control functionality is retained on the Lightning Electric if the option is present on the base vehicle.

The maximum speed of the LEV depends on a number of factors, including transmission gear ratio, rear axle/differential ratio, and controllable software parameters. Currently, the maximum speed is software limited to 65 mph on most platforms.

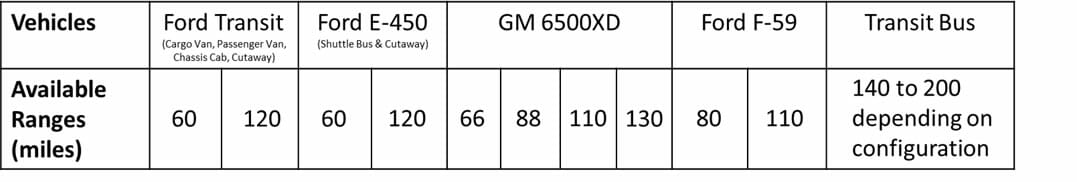

The Lightning Electric is offered in a number of different configurations, ranging from up to 60 miles to up to 130 miles. Refer to our website for specific platform details.

* All-electric range can vary depending on route or drive cycle, environmental conditions, vehicle or equipment configurations, and driver behavior

As Lightning Electric vehicles are all-electric and zero-emission—meaning no internal combustion engine—every electric device on the vehicles utilize power from the primary batteries. This outcome is the nature of all-electric vehicles, whether consumer or commercial. As such, the use of auxiliary devices can impact vehicle range. Range impacts from auxiliary equipment are analyzed by our Lightning Analytics platform and reported to you. These impacts are difficult to estimate, as they depend on a number of variables, such as environmental temperature, vehicle route and duty cycle, and use and duty cycle of auxiliary equipment.

Additional weight (whether from passengers or cargo) will require more power from the powertrain and will, therefore, negatively affect vehicle range. The precise impact varies by vehicle platform, driver behavior, and environmental conditions.

Rapidly accelerating the LEV or holding the LEV at a high rate of speed will require more power from the powertrain and will, therefore, drain batteries faster, negatively affecting vehicle range. The manner in which drivers operate the vehicle—what we call Driver Behavior—can significantly increase or decrease the Lightning Electric’s range. Lightning eMotors offers Driver Training courses to encourage driving practices that extend range and maximize efficiency.

The Lightning Electric captures energy using regenerative braking, where the electric motor acts as a generator to slow the vehicle and recharge the batteries. Regenerative braking occurs both when you lift your foot from the accelerator and when you press the brake.

As with conventional vehicles, driver behavior can impact vehicle efficiency—both positively and negatively. Drivers who pay attention and utilize the systems in place can increase the range of the Lightning Electric by maximizing brake regeneration and other good driving techniques. Lightning eMotors offers Driver Training courses to encourage driving practices that extend the range and maximize efficiency.

Towing is not recommended or supported at this time.

Considerations For Fleet Operations

We currently do not offer our powertrain systems outside of the US, Canada and Latin America. However, we are happy to discuss opportunities. Please contact our sales team to learn more.

We work with multiple EVSE partners covering all facets of charging options. In addition, we sell a range of Level 2 AC chargers and DC Fast chargers.

At this time, Vehicle-to-grid (V2G) is currently not available, but it is on our roadmap for future integration as the technology matures.

Your vehicle warranty will remain in place and be supplemented with the Lightning eMotors powertrain warranty.

Ford has announced plans to release a Class 2 Transit van in 2024, with no plans to release a Class 3 van at any time. Our Class 3 Transit van is available now.

Lightning eMotors offers a 5-year, 60,000-mile warranty on the powertrain components.

Preventative maintenance for the Lightning Electric Vehicle is minimal, consisting mainly of regular multi-point vehicle and component inspections. Since there is no internal combustion engine, there are fewer moving parts and less scheduled maintenance. Regular monitoring of the cooling system, fluid levels, suspension, brakes, and tires (as with a conventional vehicle), will lead to ideal performance.

As with any vehicle, component life and wear are dependent on drive cycle, route, driver behavior, environmental factors, and other variables. We expect the powertrain lifetime to meet or exceed the lifetime of a similarly driven internal combustion engine platform.

The main controller on the Lightning Electric detects faults and malfunctions and determines the appropriate response. Depending on the fault, the vehicle may enter a state of reduced power and/or functionality, and in severe cases, may shut down completely.

All of our powertrains are CARB certified before they are commercially available.

Battery wear and degradation arises from a variety of factors and is a natural characteristic of lithium-ion batteries, just like your cell phone battery. Temperature is one of the key impacts to life and health of batteries, Lightning Electric batteries employ precise active thermal management to keep battery temperatures in the ideal range. The life of a battery cell is measured in “cycles,” or how many times it is depleted and then charged completely. In ideal temperature and power scenarios, high-quality NMC batteries will support around 2,000 full charge-discharge cycles without showing significant degradation. The impact of fast charging is relative to the power level of the charger and how large the battery system is, so while fast charging could have a negative effect on battery health, Lightning Systems designs and sizes our battery capacities and other system features to optimize longevity.

At end of battery life customers can return batteries to Lightning for proper recycling or disposal.

Repower

Lightning Repower refers to the process of replacing existing gasoline or diesel-fueled fleet vehicle powertrain with a Lightning electric Zero Emission Vehicle powertrain. Vehicles are repowered by removing the engine, transmission, exhaust system and fuel tank and replacing those with a high-power electric motor, transmission, batteries, and electric accessories (power steering, air condition, heaters, etc.). The electric motor and transmission are configured similarly to the conventional drivetrain and secured to a frame that mimics the stock layout.

Auxiliary components are replaced to ensure all vehicle functionality is maintained (brakes, power steering, climate control, etc.) and batteries are mounted under the vehicle framework.

Repower LEVs are ideal for fleet owners who are looking to add new life to a vehicle in need for a new powertrain, decrease operating costs, update safety and drivability, meet looming ZEV mandates, or working to save on the cost of a new Zero Emission Vehicle.

Our LEV City Bus powertrain product is available as a repower only. All other LEV products are available as new or repower. Contact your Lightning sales representative for more application information.

Contact a Lightning sales representative to discuss your model and to confirm that it can be repowered with the LEV powertrain.

Repowers take place at our facility in Loveland, CO, or at one of our certified conversion partners. Many of our partners have attained Ford QVM (Qualified Vehicle Modifiers) certification and work with Lightning eMotors to deliver the highest quality, compliant repowers.

Lightning eMotors partners with some of the largest commercial vehicle dealers in the nation. There are several ways to buy a Lightning Electric vehicle, and we will work to make the process easy and seamless. Please contact us and we can walk you through it.

In the case of vehicle repowers, we sell powertrains direct and work with professional, certified upfitters to convert your current vehicles.

Please contact Lightning eMotors or an authorized reseller to receive information regarding current pricing or to place an order for a repower.

Lightning eMotors or another certified modifier can install the repower. Check with Lightning eMotors for current certified modifiers.

Any current fleet vehicle can be repowered to the Lightning Electric, provided the vehicle is a supported model year, version, and configuration of one of our products. Please contact Lightning eMotors for details regarding the possibility of repowering your fleet.

There are many upfitters that provide product and installation when it comes to shelving, cabinets, seating, etc. Lightning eMotors only provides electric repowers. Lightning eMotors is happy to connect customers with quality upfitters to meet their specific needs. Please contact a Lightning sales team member.

In the case of repower or retrofit vehicles, the engine we replace is generally destroyed and/or used for spare parts. In the case of a new vehicle, we generally sell the engine/transmission/exhaust/fuel tank on the open market. We are working with all of the OEM’s to provide us with “gliders” (vehicles without engines/transmissions/exhaust systems/fuel tanks) – but only some of our OEM partners will provide us with gliders today

Lithium-based EV battery packs are not easily recyclable, although there is a push in the industry to address this. However, there are opportunities to redeploy EV batteries in less-demanding applications such as microgrids and mobile charging stations

Charging Solutions

Lightning eMotors offers a comprehensive range of EV charging stations which includes Level 2 AC charging and DC Fast charging.

Level 2 AC charging works by delivering AC (alternating current) electricity to the vehicle, where it is converted to DC (direct current) electricity which charges the batteries. Level 2 refers to the AC voltage, which is 220V, and the charging power, which is between 6.6kW and 19.4kW.

DC Fast Charge stations convert the site’s AC electricity to DC, which is delivered to the vehicle, where it charges the batteries. DC Fast Charge can charge a vehicle more quickly than Level 2 AC charging, with rates up to 50kW and beyond.

The charge time depends on several things, including the state of charge (SoC) of the batteries before charging begins. If the vehicle was driven to “empty”, then a rough estimate of the charging time is:

80% of the nominal capacity of all the batteries

divided by

the charging rate of the charging station

For example, a Lightning Electric Ford Transit with two 43kWh batteries (a total of 86kWh) and which is limited to 6.6kW charging rate, being charged with a 7.2kW Level 2 AC charger might take:

86 x 0.8 / 6.6 = 7.2 hours

If using a 25kW DC Fast Charge station, charging would take:

86 x 0.8 / 25 = 2.8 hours

In reality, charging times will be somewhat longer because the charging rate reduces as the batteries reach full charge. In addition, if the vehicle’s heating or AC is running, or if the vehicle’s battery thermal management system is running, charging will take longer. Finally, some vehicles limit the maximum charging current, which also increases the charging time.

The Level 2 AC charging stations use SAE J1772 standard connectors to the vehicle. The DC Fast Charge stations offer SAE J1772 CCS Type 1 Combo, or CHAdeMO, or both. Our vehicles are compatible with SAE J1772 CCS Type 1 Combo, and are not compatible with CHAdeMO.

All installations should be performed by certified installers, following local code and permit requirements. Installing a Level 2 AC charging station is usually straight forward, requiring a single phase of 208/240VAC and a sufficiently rated circuit and breaker. Installing the higher-power DC Fast Charge stations usually requires three-phase provision. This is likely to require an appropriate permit.

Yes. A combined RFID / credit card reader is a standard feature on some of our charging stations and optional on all of the others.

All of our charging stations support Ethernet network connection. 3G/4G and/or Wi-Fi are available as options.

Yes. All of our chargers support OCPP (Open Charge Point Protocol). The user must select a third party software solution, such as EVConnect, greenlots or The Mobility House.

Some states or local jurisdictions offer vouchers or other financial incentives for purchasing and/or installing charging stations. Some utility companies also offer programs for subsidizing the cost of charging stations.

Financial Questions

Contact a sales representative for vehicle price ranges.

Contact our voucher and incentive experts for more information on funding available in your area.

Lightning eMotors can facilitate financing options including lease, rental and third party financing. Please speak to your sales representative for more information.